Services

Panel Forming

Heavy Press Factory & Medium Press Factory

- Production of automotive components using state-of-the-art press machines, including mechanical and hydraulic presses

- Having Grade A quality from SAPCO company for the production of automotive components, and employing a specialized press machine for waste materials in the pressing workshop

- Production of household appliance components with the highest quality and the most experienced operators

- Production of automotive components with over two decades of manufacturing experience and the highest quality

Maintenance and repair of molds

The main task of the High Mold Maintenance Unit is to increase the efficiency percentage of the delivered molds. To achieve this, the factory must be equipped with a strong preventive maintenance team. When the molds are transferred from the production line to the maintenance unit, they all undergo a detailed inspection.

It is worth mentioning that at this stage, specialized individuals with specific expertise, including welding and tri-out machining, are utilized, as each repair may require specific skills.

Ultimately, the goal of the supervisor and the planning unit of the High Mold Maintenance is to minimize emergency repairs by conducting periodic and preventive maintenance in this unit

Component Manufacturing

Production mechanism

To transform a hard and cold steel sheet into a usable component in a car, we navigate a challenging path, and we are committed to designing and directing the highest quality, cost-effective, and technological route for the production of your automotive parts.

The production process at Asia Khodro Synchronization Company takes place in ten different halls, equipped with approximately one hundred mechanical and hydraulic presses, ranging from 63 to 1250 tons, twenty-two assembly robots, three laser and plasma cutting robots, and three mechanized primer painting lines.

1. Tool and Die Factory

In this tool and die factory, specialized steel molds for presses in sizes G1 to G5 are designed, modeled, and manufactured.

2. Sheet Metal Cutting Factory

Steel sheets are cut to the optimal size for each component based on the designs provided by the technical and engineering unit, and then transferred to the press shop.

3. Pressing Operations

The cut sheets in these workshops undergo pressing and forming operations.

4. Laser and Plasma Cutting Robots

After the forming process, pressed components are transferred to this section for trimming and precise hole drilling. The advantages of laser and plasma cutting include very high speed and precision in cutting and hole drilling.

5. Welding and Hemming Assembly Robots

Automotive assemblies requiring multi-piece assembly are welded by welding robots, and the surface and double part are assembled on top of each other by hemming robots.

6. Plating

Internal body components, such as the front bumper reinforcement for Peugeot 405, undergo the galvanized plating process in this section.

7. color

There are three separate primer painting lines. Initially, the produced products are degreased and washed. Then, for the primer paint to penetrate the component, the parts are phosphated. Subsequently, they are dried in the pre-heating stage and prepared for the paint spray. After the primer painting stage, the painted components are finally transferred to the baking furnace.

8. Packaging

After all stages of painting and waxing, if necessary, the components are placed in bubble wrap, and impact-absorbing foams are installed. Subsequently, they are placed inside 5-layer cardboard boxes and finally wrapped in shrink wrap.

9. Storage and Shipping

Each packaged component is placed in a designated section of the warehouse according to the scheduled shipping plan. Subsequently, under the supervision of the quality control unit and in coordination with the esteemed sales representatives, the loading process is carried out, and the products are dispatched to all parts of the country.

Assembly

The produced Parts

The products of this company are divided into two main categories: those used in the production lines of the country’s automotive industry and those used in the market for spare parts. We take pride in being the provider of the most comprehensive and highest-quality range of metal body products for passenger cars in the country. The company’s products are categorized into three groups for the vehicles of Iran Khodro, SAIPA, and Renault Pars, and the diversity of these items includes the following car models:

Peugeot 405, Peugeot SLX, Peugeot Pars, Peugeot 206, Samand, Arisan, Pride Saba, Pride 132, Tiba, Tondar 90, and Dena.

Raw materials

The quality and suitability of raw materials are essential elements of high-quality and premium production. The raw materials used in the production lines of Asia Khodro Synchronization Company include various types of sheet metal, primer paint, cardboard, shrink wrap, etc. All these materials are selected from among the top domestic manufacturers based on the latest industry standards by experienced experts in the procurement and quality control unit of Asia Khodro Synchronization Company.

Color

Introduction to Painting Lines

- Equipped with three separate semi-automatic lines for liquid and powder (electrostatic) paint spraying, along with washing and degreasing using reputable materials supplied by standard-compliant companies recognized by domestic automakers.

- The primer paint used in Asia Khodro Synchronization Company is of the highest quality, containing corrosion-resistant zinc phosphate pigments. It exhibits high resistance to moisture, oil-based solvents, and mineral oils, and is sourced from reputable automotive paint factories with industry standards.

- The laboratory is equipped with various industrial paint testing devices, such as cross-cut, bending, salt spray, impact testing, etc.

- Waxing of components for filling gaps and sealing the edges of assembled hemmed parts, using waxes commonly used in the production lines of domestic automakers.

- Quality control stations in the paint halls for controlling the input of raw materials and 100% inspection of the produced products, accompanied by the installation of quality labels on all components.

- Packaging of products with 3-layer and 5-layer cardboard boxes, along with impact-resistant foam, bubble wrap, and shrink wrap for protecting components against dust, moisture, and impact.

Latest News

Hamgam Industrial Group at the Endowment Exhibition | A Narrative of Development, Employment, and Social Responsibility

Hamgam Industrial Group showcased a strong and influential presence at this year’s Endowment Exhibition, presenting its latest capabilities and achievements in the automotive and national production sectors

At a ceremony attended by the President, Engineer Mohammadreza Jabbarzare highlighted the role of entrepreneurs and philanthropists in national development and urged practical action to revive the Zayandeh Rud River.

“Register the Zayandeh Rud in the name of Iran, but let water flow through it…”

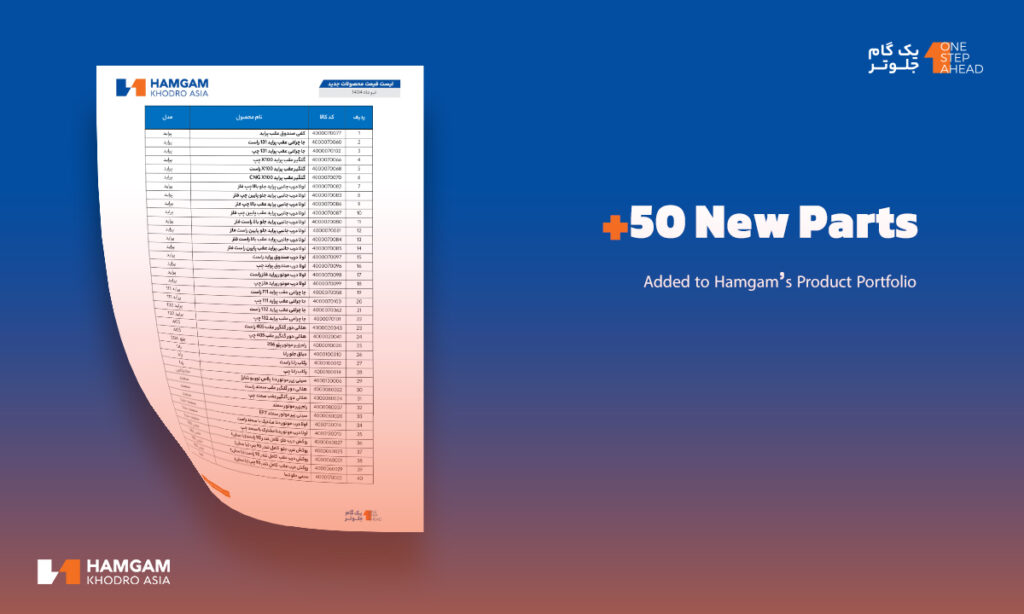

With the addition of 50 new products, the total number of our automotive body parts in the aftermarket has now reached an impressive 224 pieces!

Hamgam Khodro proudly announces the addition of 50 new products to its aftermarket body parts collection. This significant step reflects our commitment to expanding coverage and offering more options to the market.

Good news from Hamgam Khodro Asia for its customers and partners: Iranian car rims have been added to our product lineup!

Good news from Hamgam Khodro Asia for its customers and partners: Iranian car rims have been added to our product lineup!

Visit of Mohammadreza Jabbarzare, CEO of Hamgam Holding, to the 7th Sadra Event at Najafabad Branch of Islamic Azad University

Mohammadreza Jabbarzare, CEO of Hamgam Holding, during his visit to the 7th Sadra Event at Najafabad Branch of Islamic Azad University, expressed his satisfaction with the remarkable progress in collaboration between industry and academia, describing the event as a valuable opportunity for students to explore suitable career paths. According to the provincial reporter of Iscanews…

The Strong Presence of “Hamgam Khodro Asia” at the 2025 International Auto Parts Exhibition

As one of the most pioneering and innovative companies in the country’s automotive industry, Hamgam Khodro Asia showcased once again its position as a reputable and trusted brand among industry professionals through its strong and prominent presence at the 2025 International Auto Parts Exhibition. The exhibition, held with the participation of the most reputable domestic…

In Step with Quality, Leading the Industry:An Interview with Engineer Jabar Zare, Founder and CEO of Hamgam Khodro Asia at the 20th Tehran International Auto Parts Exhibition

On the sidelines of the 20th Tehran International Auto Parts Exhibition, an exclusive interview was conducted with Engineer Jabar Zare, CEO and founder of Hamgam Khodro Asia Industrial Group

Visit of Masoud Sarrami and Dr. Shariati to the Hamgam Industrial Group

A visit to the Hamgam Industrial Group facilities was conducted during a ceremony attended by a prominent entrepreneur of Isfahan Province, a Masnavi researcher and author from Isfahan, as well as the CEO of Hamgam Industrial Group.

When you stand beside a successful manager, their influence on you is just as powerful.

The distinguished author and Masnavi researcher of Isfahan Province said, in a gathering of the managers and supervisors of the Hamgam Industrial Group:

“When you stand beside a successful manager, their influence on you is just as powerful, and good friends and good leaders are blessings that lead to success.”

“Our achievements have been made possible because of you. I will stay in Isfahan until the last day of my life.”

The prominent entrepreneur of Isfahan Province, during his visit to the Hamgam Industrial Group facilities, said:

“It fills me with pride to see people who have stayed despite all the hardships and continue to work tirelessly.”